Due to their excellent properties, chill casting is used in almost all branches of industry.

Forms casting

A precision casting process

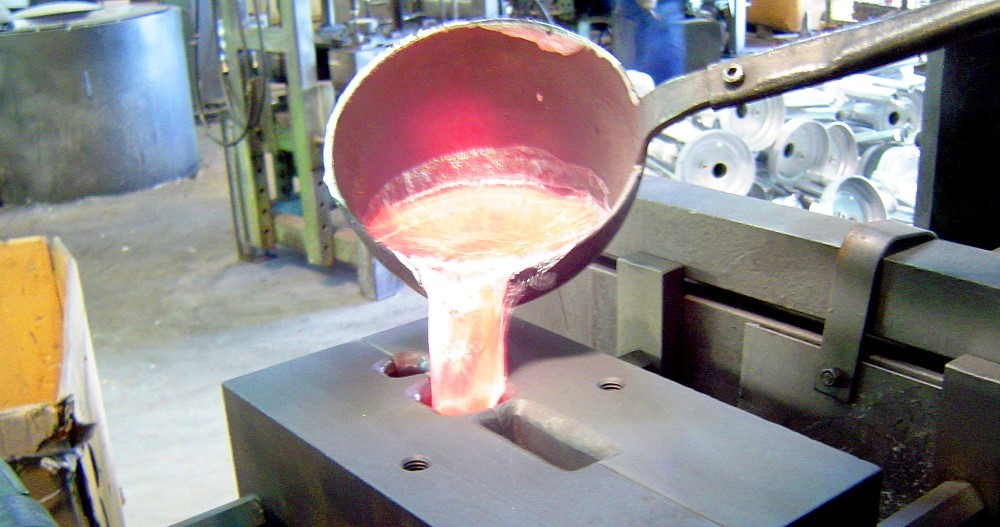

In Kokillengießverfahren the liquid aluminum melt is poured through a so-called pouring funnel into the mold, which fills only by gravity.

Due to the rapid heat dissipation, the mold aluminum castings have a fine-grained, dense structure with ideal mechanical properties, high dimensional accuracy and surface quality as well as perfectly contoured reproduction.

Finished cast-in parts, such as threaded bushings or bolts as well as holes and openings can be easily integrated into the component.

Due to these excellent properties, chill casting is used in almost all branches of industry. Even the demand for gas- and liquid-tight fittings is fully met by this method.

Chill casting - Aluminum is poured into a mold

Economics

Chill casting can be economical even if the required quantities are in the middle casting range (about 1000 castings).

At high volumes, the fast, efficient casting sequence and relatively little reworking of the raw casting is a factor.

The profitability of chill casting and its processing advantages increases with the demands on quality and surface quality of the aluminum casting.

Casting process

Casting under the action of gravity into permanent metal molds, the molds (tools).

These parts are designed to remove the finished castings in two or more parts. Due to the high thermal conductivity of the mold accelerated cooling of the solidifying melt takes place.

This results in the fine-grained, dense structure with very good strength properties.